Guilford of Maine

Guilford Woolen Mill Finishing Room Crew, ca, 1890

Guilford Historical Society

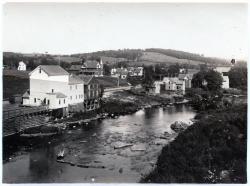

In 1824, the first dam across the Piscataquis River in Guilford was erected, and another sawmill built alongside it on the north side of the river by Robert Herring Jr. and S&J Morgan. It later changed hands a few times, Hobart & Harris Company were among its owners, until 1881 when it was sold to Piscataquis Woolen Company, owned by M.L. Hussey, H. Douglass, J. Pollock, D.R. Straw, Z.L. Turner, and F.B. Stevens. Years later, The Draper Corporation, utilizing part of the premises, installed sawmill equipment and manufactured bobbins for use in the textile industry on the spinning frames. This was the second textile mill in town.

Piscataquis Woolen Company Mill, Guilford, 1912

Guilford Historical Society

The first was built on the south side of the river at Oak Street in 1865 to take advantage of the water power at that site. A long shaft running up the bank to the mill was connected to a waterwheel which supplied most of the power necessary. Known as Guilford Woolen Company, it was leased to William Appleyard in 1868 who later purchased it (1876) and leased it to the Piscataquis Woolen Co. mentioned above. In 1884, this mill was lost to fire, and in 1901, the facility on the north side which had recently been expanded, was severely damaged by a flood.

M.L. Hussey Woolen Company Mill, Guilford, 1918

Guilford Historical Society

In 1904, the M.L. Hussey Woolen Co. constructed a new facility on the Appleyard site, south side of the river, with partners C.D. Shaw, F.B. Pease, and A.C. Houston. It was one of the best equipped mills in all of New England, producing cashmere and dress goods. This plant was enlarged and a floor added in 1907. The following year, the log jam and flood mentioned above occurred, sending two and a half million feet of logs through the windows and inundating the boilers in both mills.

Hussey's Woolen Mill, Guilford, ca. 1920

Guilford Historical Society

In 1917, Herbert Gray of Old Town Woolen Company purchased the south side mill and continued to make improvements, becoming well known for their Moosehead Blanket line. In the flood April of 1923, water overflowed the concrete abutments, rushed around the side through the coal pits and burst through the windows, carrying tons of coal and gravel, packing the boiler room and dye house to a depth of three feet, and destroying dye tubs and other machinery with gravel and lighter stones.

Guilford Woolen Mills, ca. 1920

Guilford Historical Society

New Addition to Guilford Woolen Mill, ca. 1930

Guilford Historical Society

Armed National Guard Troops at Guilford Woolen Mill, September 17, 1934

Guilford Historical Society

In 1934, organizers attempted to establish a union at the mill. Tensions ran high on both sides of the issue and finally, the National Guard was called in to maintain peace until the matter could be quieted. Soon thereafter the mill went into receivership with Eastern Trust Company. In 1936, Willard Cummings assumed leadership at the trustees request and accomplished what many said could not be done. He added product lines, an outlet store, and new fibers, turning the company around and became a solvent manufacturing concern once again. In 1943, Mr. Cummings purchased controlling interest in Piscataquis Woolen on the north side, and Guilford Woolen Mills Company was created, combining the ownership into one firm. The Draper Mill relocated and built a facility on Water Street. Innovations included 94 modern automatic looms replacing 40 hand looms. In 1947 a sales agency was developed with an office in the Empire State Building in New York City to further market the ever increasing fabric offerings. In 1948, a ramp was built across the river to connect the two Guilford mill properties, and two other enterprises, Sangerville Woolen Co., and Carleton Mill were acquired.

In 1950, Willard Cummings died and his son, H. King Cummings was elected president of the company. Many more improvements were made, seemingly annually to update machinery and enlarge the capacity over the following years. In 1954, the Willard Division in Eastport was purchased, and in 1958, the D.E. Cummings holdings in Newport was added for further diversity, and the entire collaboration was incorporated as Guilford Woolen Mills, Inc. to effectively unify marketing, research and sales.

Guilford Industries, Inc. Advertisement

Guilford Historical Society

In 1962, the process of bonding foam backing was developed opening new frontiers in the manufacturing process, they established a Five Year Leadership Plan, the name was changed to Guilford Industries, Inc., and they purchased a California firm to establish their presence in the carpeting business, They also acquired Johnson Woolen of Connecticut adding raw wool scouring and grading of fleece. By the mid-70’s, the apparel market had become unpredictable and they began developing drapery and upholstery fabrics as well. Office panel systems, constructed of cloth over metal frames were becoming popular at this time, and the newly developed flame retardant process developed at Guilford made them an instant industry leader. In 1979, Len Saulter came in as president and pushed for concentration in total office systems, making fabric for everything from panel cloth and drapery to ceiling treatments and vertical blinds.

In 1982, the company was sold to Thomas H. Lee Company who streamlined financial operations, acquired Hayward-Schuster Woolen Mills in East Douglas, Massachusetts, opened more outlet stores, upgraded equipment and then sold the whole business to Interface Flooring in 1986. The following year on April Fool’s Day, the most devastating flood in the town’s history occurred. The dye house was awash with debris and oil as two 10,000 gallon fuel tanks were breached and their contents spilled into the river and throughout the mill; machinery was ruined and buildings were severely damaged. Faithful employees and many other community members worked long and hard to clean up and regroup. In 1988, the name again changed, this time to Guilford of Maine, Inc. In 1989, new corporate offices were built on Oak Street and a new mill store and training office was opened on Elm Street. In 1996, the Leonard Saulter Facility was constructed on Water Street, the most modern yarn manufacturing facility of its time. The company acquired Intel and Toltec Fabrics and Interface Interior Fabrics, Inc. was formed. By 2000, they also added Interface Fabrics, Ltd of the United Kingdom, purchased Chatham, Inc., and Teknit, and again changed their name to Interface Fabrics Group. Following the events of Tuesday, September 11, 2001, and our country going to war in 2003, the global economy slowed considerably and the effects were felt at Interface. The company was sold in 2008 to Sun Capital Partners, an investment group, and reorganized as True Textiles, Inc.